Product information "FCI-InGaAs-XX-XX-XX InGaAs Photodiode Pigtail Assemblies"

900 to 1700 nm; Active Area 0.004, 0.011 mm2; AA Dia. 0.075, 0.120 mm; Rise Time 0.2, 0.3 ns; Responsivity 0.75 to 0.95 A/W; Capacitance 0.65, 1.0 pF; Package TO-46, Ceramic Substrate, Connector Type FC, SC, ST

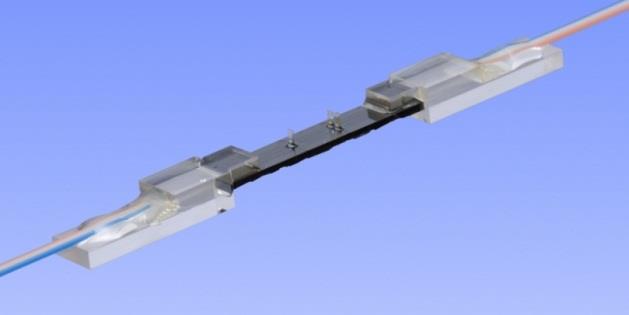

OSI Optoelectronics’ FCI-InGaAs-XX-XX-XX series of high-speed, IR-sensitive InGaAs photodiodes with active area diameters of 75 and 120 µm are part of OSI Optoelectronics’s family of high-speed IR sensitive detectors with fiber pigtail package.

The single mode (SM) or multi mode (MM) fiber is optically aligned to either the hermetically sealed InGaAs diode in TO-46 lens cap package enhancing the coupling efficiency and stability, or directly to the InGaAs diode mounted on a ceramic substrate.

High responsivity and low capacitance make these devices ideal for very high bit rate receivers used in LAN, MAN, WAN and other high speed communication and monitoring/instrumentation systems. Angle polished connectors and custom packages are also available.

For a solution involving FC connector and TO-46 attachment, users may consider either FCI-InGaAs-75-SM-FC or FCI-InGaAs-120-SM-FC in single mode operation. Similarly, the multi-mode variant is available in FCI-InGaAs-120-MM-FC using 62.5/125 µm fiber. The back-reflection of -30dB typical is to be experienced in multi mode (MM) based solutions.

Key Features:

- High Speed

- High Responsivity

- Spectral Range 900nm to 1700nm

- Low Back Reflection

Applications: Very High Bit Rate Receivers Used in LAN, MAN, WAN; High-speed Optical Communications; Gigabit Ethernet / Fibre Channel; SONET / SDH, ATM; Optical Power Monitoring / Instrumentation