Product number:

C015021-6

Manufacturer:

Nanolap

Available stock:

60

Product information "26M-0.3-5D Polishing Film"

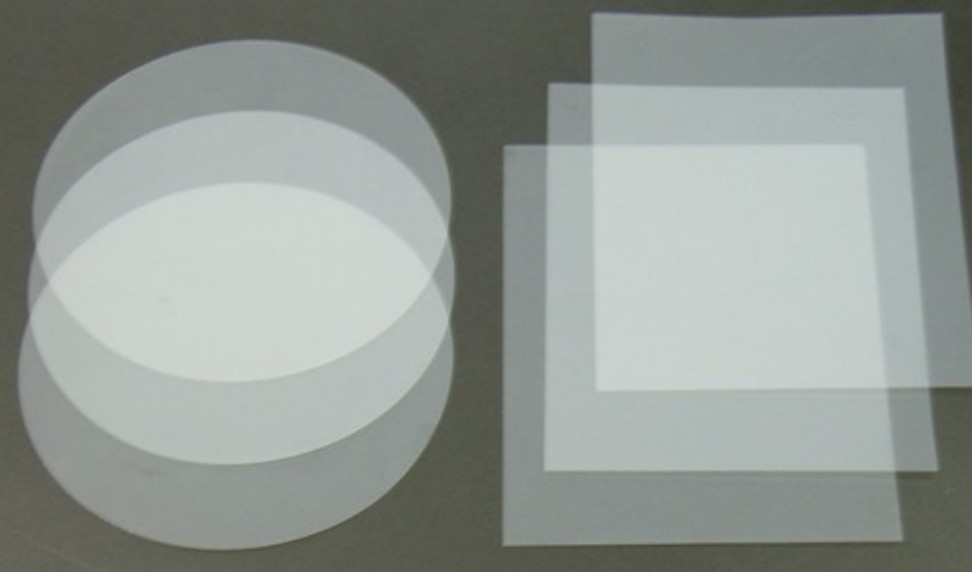

5 inch Disc; Grit 0.3 µm; Aluminium Oxide; Stainless Steel Ferrule; no PSA

The 26M-0.3-5D fiber optics polishing film from Nanolap comes in a pack that contains 10 pieces.

Manufacturer "Nanolap"

Nanolap Technologies, LLC provides solutions for demanding surface finishing applications. The company offers a broad array of abrasive products for use in lapping, polishing, microfinishing, fining, sanding, honing, buffing, cleaning and other surface generation applications.

Related links of the manufacturer