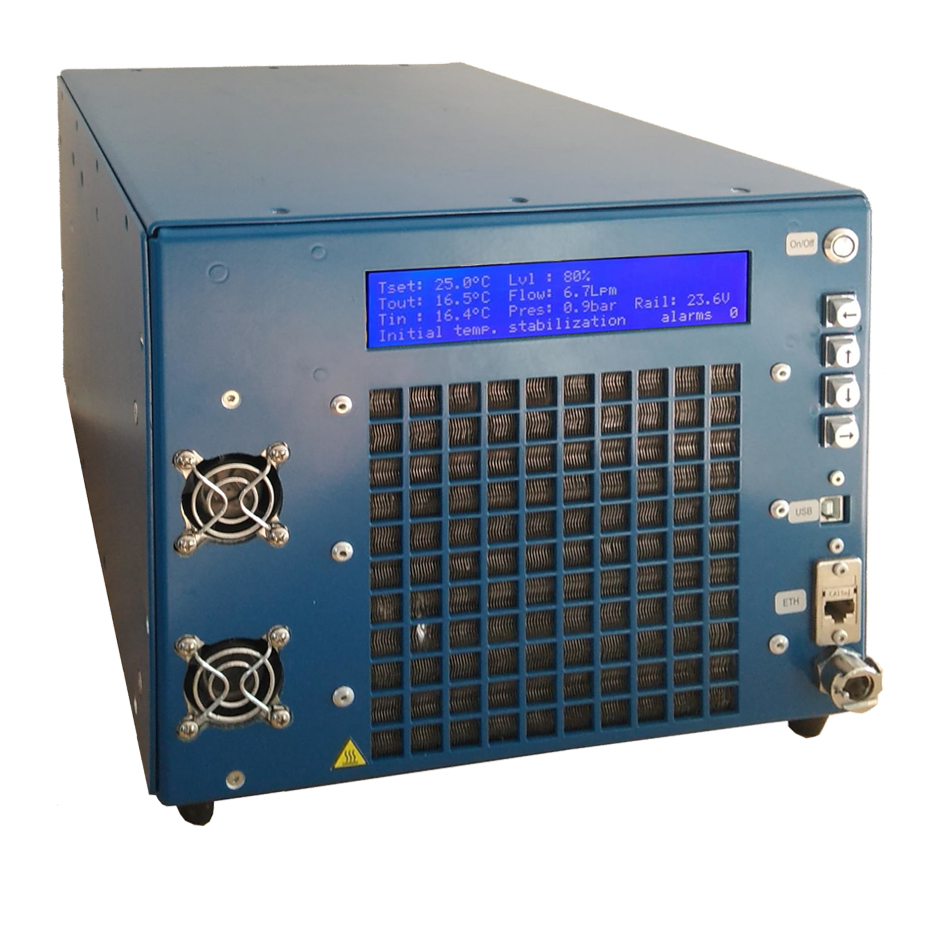

Product information "mRC-C-450-100/240 mini Recirculating Chiller"

Vapor Compression Chiller; 450W @+25°C; 230VAC; 2lpm; USB/ Ethernet; Benchtop

Key Features:

- Miniature Recirculating Water Chiller

- Compact Size, Easy to be Integrated in Customer Application

- User-Definable PID Parameters and Fan Velocity

- Calm Operation With Low Vibration and Noise

- Ideal for Water Cooling Tasks up to 450 W

- IoT Ready: Remote Operation, Monitoring and Service over Integrated Ethernet Interface

Full chiller power in a shoebox form factor: the mRC-C-450-100/240 mini recirculating chiller provides to 450 W cooling capacity and contains a compressor-based refrigerant circuit as well as a closed, recirculating coolant (water) circuit that is pressurized – all that in a compact, 350 x 290 x 230 mm housing. This small size is enabled by utilizing a miniature rotary compressor, customized miniature evaporator and condenser. On the coolant side, pressurizing the circuit allows a very small tank, and a compact centrifugal pump also contributes to reduced space requirements.

Due to the speed-controlled compressor, the mRC-C-450-100/240 chiller offers low vibration and noise throughout the compressor’s BLDC speed range. Further features are automatic fill and drain of the coolant circuit, global operability due to a universal 90 to 264 VAC power supply, and an integrated Ethernet interface allowing remote operation, monitoring and service.

Specifications:

- Cooling Capacity: 300 W (Twater = +20°C, Tambient = +40°C) to 500 W (Twater = +20°C, Tambient = +20°C)

- Temperature Stability: +2/-1.5 K Over-/undershoot at 250 W Heat Load ON/OFF, Down to 0.05 K Continuous Operation

- Available Pressure Head: 1.5 bar @1 lpm; 0.5 bar @5.5.lpm

- Noise Level: 63 dBA (fan 40%, compressor 100%)

- Control: Local, USB/Serial, Internet (Web Browser) via Ethernet (IoT Ready)

- Interlock I/O Alarms: Liquid Level, Tank Pressure, Coolant Feed Temperature, Coolant Flow Rate, Condenser Pressure

- Power Supply: 90 to 264 VAC, 24 VDC Derivative Available on Demand

- Power Consumption: <300 W

- Dimensions: 350 x 280 x 230 mm, Main Body Without Filter

- Weight: 13 kg

- Approval: CE

Applications: Water Cooling of Lasers and Other Applications; Integration of Water Cooling Capabilities in Systems with Limited Space