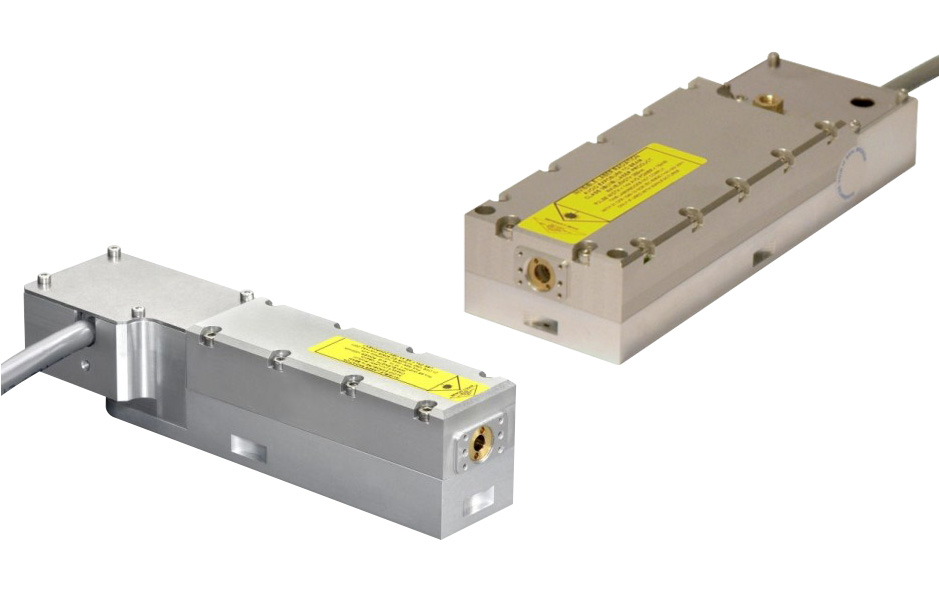

Product information "STx Series High-performance Triggered Microchip DPSS Lasers"

266, 355, 532, 1064 nm; Output Energy >0.75->14 µJ; Repetition Rate 0.5-100 kHz; Peak Power >1->30 kW; Pulse Width 0.3-8 ns; Pulse Creation Delay <70-<160 µs

For generating high peak power pulses of a few hundred picoseconds, Teem Photonics’ STx Series of high-performance triggered microchip lasers are economical, compact, and reliable, within a sealed package ensuring incredibly long lifetime even in harsh industrial environments.

The triggered STx Series offers the highest peak power and shortest pulses of Teem Photonics’ entire microchip DPSS laser family and span the full wavelength spectrum down to 266 nm. With these devices, the user is able to trigger pulse emission on demand from single shot to 100 kHz.

The STG, STV and STU models’ visible (VIS) and ultraviolet (UV) wavelengths are generated from the harmonic conversion of an IR passively Q-switched Nd:YAG microchip engine.

Key Features:

- Ultra-short Pulses: 0.3 to 8 ns

- Triggered: Single Shot to 100 kHz

- Wavelengths: 266, 355, 532, 1064 nm

- Multi-kW Peak Power: >1 to >30 kW

- Excellent Beam Quality: Beam Profile Gaussian TEM00, M²<1.2 to <1.4

- Efficient, Air-cooled

- Sealed Package, Extremely Long Life

- Output Energy: >0.75 to >14 µJ

- Repetition Rate: 0.5 to 100 kHz;

- Pulse Creation Delay: <70 to <160 µs

Applications: Instrumentation; Ranging; LIDAR; Differential Absorption LIDAR; Supercontinuum Generation; Distributed Temperature Sensing; Raman Spectroscopy; Biophotonics; Micro-dissection of Cells; Brain Nanosurgery; Protein Cross-linking