Product number:

C019316-6

Manufacturer:

Corning

Available stock:

495

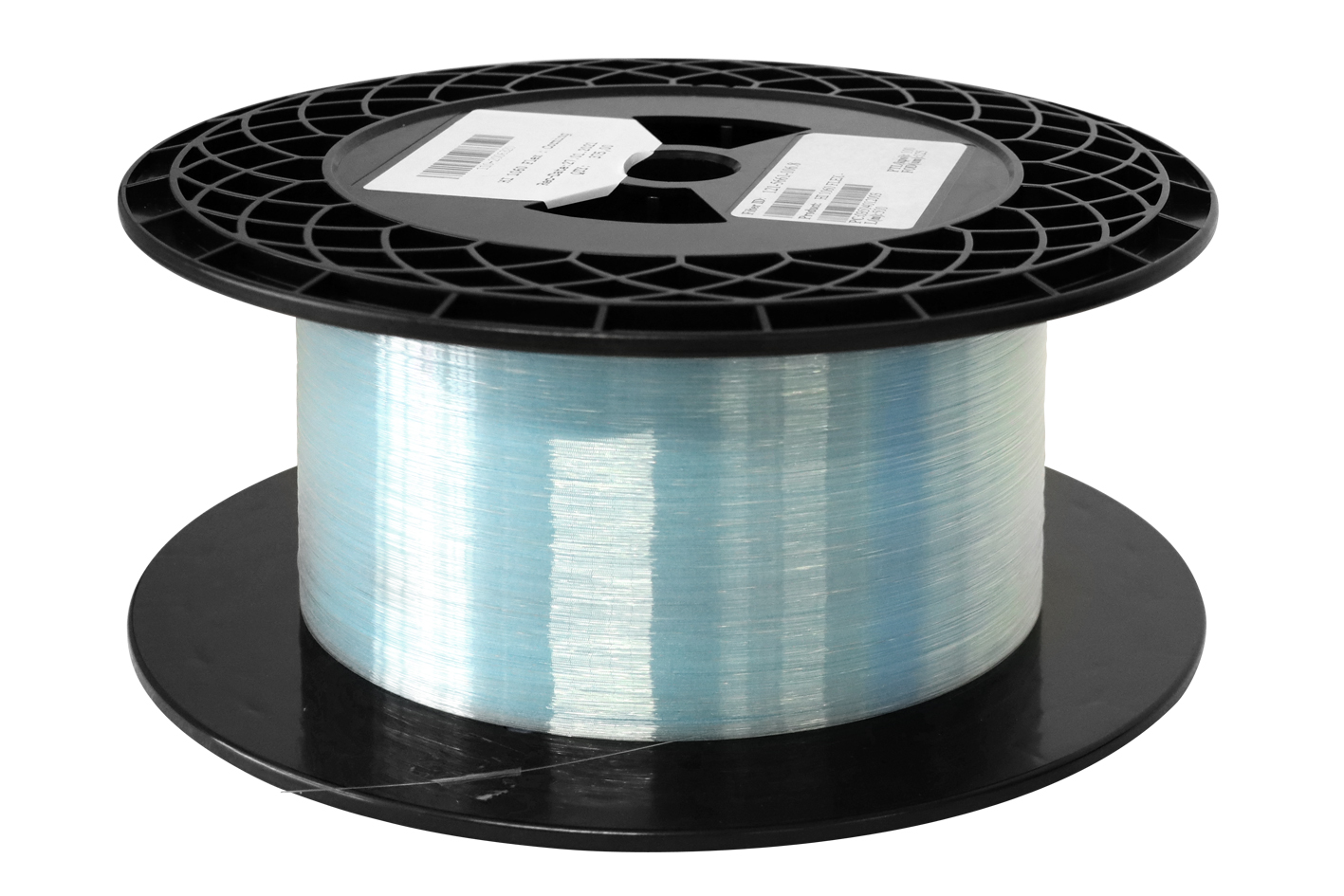

Product information "SM Fiber, 1290-1625nm, bend insensitive, SMBI-5-XMT"

Non hermetic, minimum bend radius: 5mm, mid-temperature acrylate coating type: 180°C.

Single mode mid-temperature specialty optical fibers.

Key optical specifications

| Operating Wavelength (nm) | 1310, 1550 |

| Cable Cutoff Wavelength (nm) | ≤ 1260 |

| Maximum Attenuation (dB/km) | 0.38 @ 1310 nm |

| 0.24 @ 1550 nm | |

| Mode-field Diameter (µm) | 8.6 ± 0.4 @ 1310 nm |

| 9.65 ± 0.5 @ 1550 nm |

Key geometric, mechanical and environmental specifications

| Cladding Outside Diameter (µm) | 125 ± 1.0 |

| Coating Outside Diameter (µm) | 245 ± 10 |

| Core-to-Cladding Offset (µm) | ≤ 0.5 |

| Standard Lengths | 500 m, 1 km, 2 km, 5 km |

| Proof Test (kpsi) | 100 |

| Operating Temperature (°C) | -60 to 180* |

| Coating | Mid-Temperature Acrylate Optional Hermetic Layer |

* also fully qualified at 165 °C

Performance characteristics*

| Numerical Aperture | 0.12 |

| Bend Loss (X mm radius; 1 turn) (dB/turn) | ≤ 0.10 @ 1550 nm |

| ≤ 0.30 @ 1625 nm | |

| Recommended Minimum Bending Radius (mm) | 5 |

* Values in this table are nominal or calculated values

Manufacturer "Corning"

Corning’s specialty fiber is optimized for diverse applications and plays an integral role in many high-performance telecommunication devices including optical amplifiers, transmission lasers, and external modulators; and is widely deployed in fiber-optic gyroscopes and navigation systems. Our core expertise in optical fiber enables us to produce specialty fiber with the industrys leading technical specifications.

Related links of the manufacturer