Optical Windows

Product Portfolio

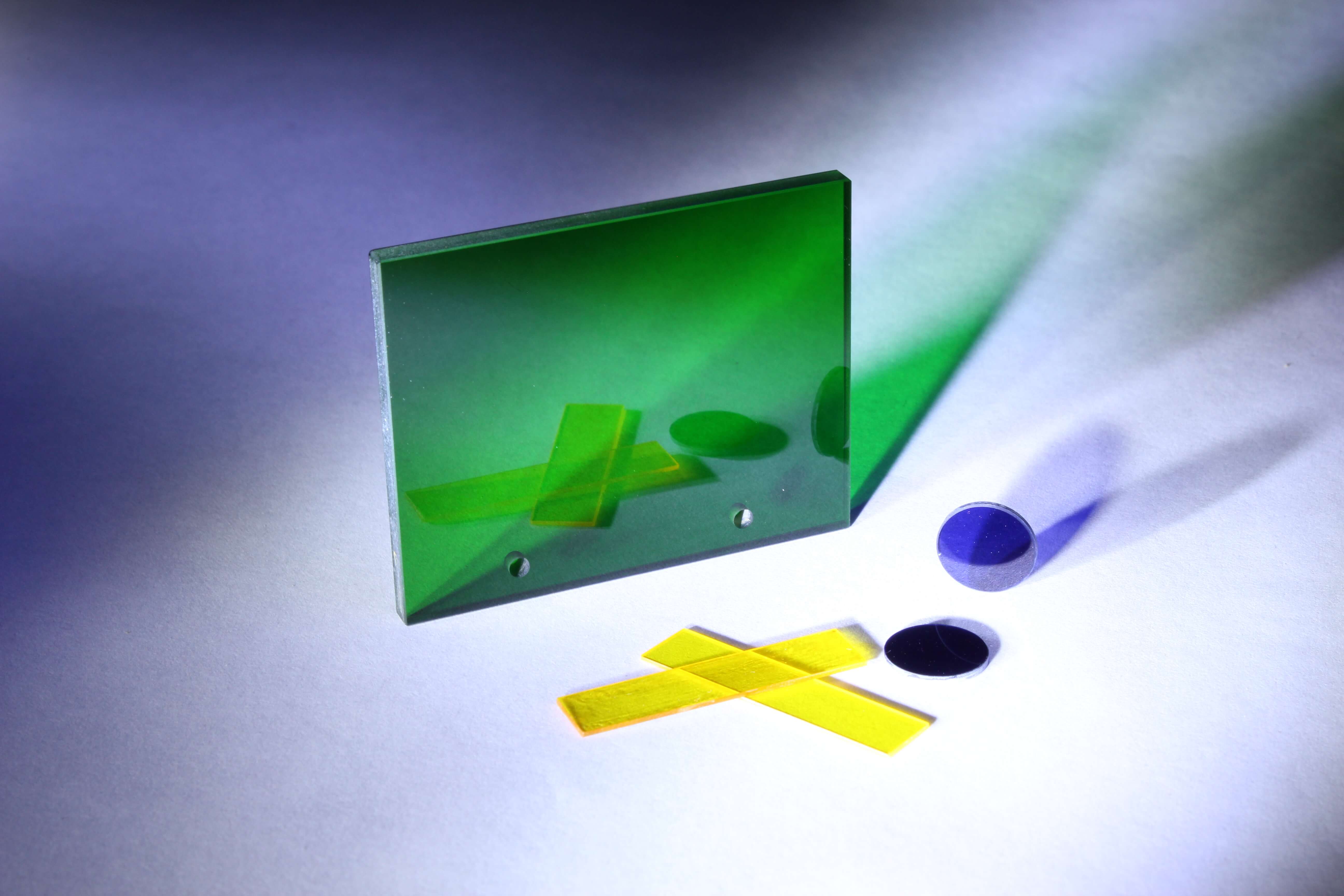

Our supplier designs and produces customized optical windows exactly tailored to the customer’s requirements. Available in round, rectangular or elliptical shape, protective windows as well as high-precision windows for laser applications with dimensions ranging from 3.0 mm to 200.0 mm are manufactured from a broad range of materials from optical, quartz or borosilicate glass to crystal materials like Si, Ge, MgF2, CaF2, Sapphire, etc.

Please contact the AMS Technologies optical solutions experts to discuss your customized optical window solution that exactly matches your application’s requirements..

Related Products

Precision optics of this kind, manufactured and coated to very specific and demanding tolerances, is in great demand by our customers. Other available components that can be realized include optical mirrors, spherical lenses and molded glass aspheric lenses, cylindrical lenses, prisms or optical filters – all featuring high precision, lowest tolerances (dimensional and angular) and special coatings for exotic wavelengths, even into the UV spectral range.

Beyond these optical components, AMS Technologies carries a broad range of complementary products such as optical mounts, rotary and translation stages, optical tables, breadboards and platforms, lasers and light sources as well as a broad range of optical test and measurement equipment.

Definition

An optical window is transparent for a certain wavelength range, which is determined by the window’s optical material and any possible coating. An optical window has no optical power, so the light passing through a window is neither converged nor diverged.

Optical windows are used to separate two different atmospheric environments with different physical properties (e.g. pressure, temperature) or chemical compositions, while allowing light to flow from one environment to the other as unobstructed as possible.

How to Select Your Optical Window

Flatness:

Flatness defines the value of the deviation of a window from a perfectly flat surface. Flatness is usually measured by bringing the surface of the window into contact with a very flat reference surface (optical flat). The curvature of the resulting fringes is a measure of flatness and is expressed in fractions of the wavelength of the light emitted by the test light source.

Surface Finish:

The surface finish or surface quality of an optical window is a value that evaluates surface irregularities as they may occur in the manufacturing process. Such irregularities can have a very small effect on the window’s scattering and optical transparency and are of particularly important in demanding applications with high optical power. Surface finish is most often defined by the "scratch-dig" specification, which gives the visual appearance of the width of a scratch and the diameter of a maximum allowable dig in a combination of two dimensionless numbers.

Brewster Angle:

The value for an optical window’s Brewster angle indicates the angle at which only the parts of the incident light polarized perpendicular to the plane of incidence are reflected. This reflected light is then linearly polarized. In contrast, the light refracted in the window is only partially polarized.

Angle of Total Internal Reflection:

An optical window’s angle of total reflection indicates the angular value above which all incident light is completely reflected at the interface between the window material with a high refractive index and the atmosphere behind it (usually with a lower refractive index). Thus, no portion of the light entering at an angle equal to or beyond the angle of total reflection can pass through the window.