Aspheric Lenses

Aspheric Lenses available from Stock

For a long time, aspheric lenses have been considered optimal for refracting light but at the same time too expensive to manufacture – inhibiting their broad use. Today, our manufacturing partner uses a precision glass molding technology to produce aspheric optics in high volume while maintaining the highest quality at an affordable price.

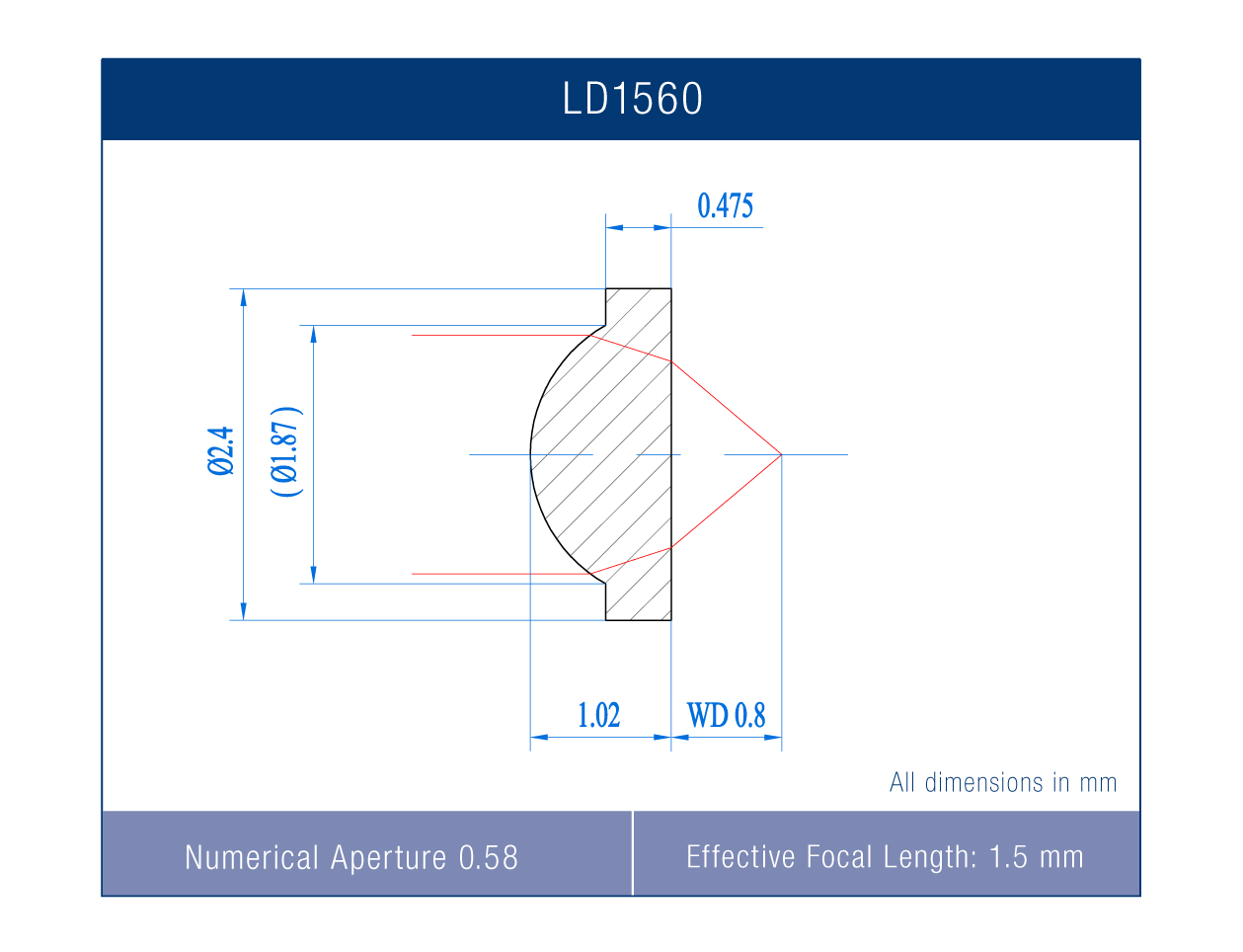

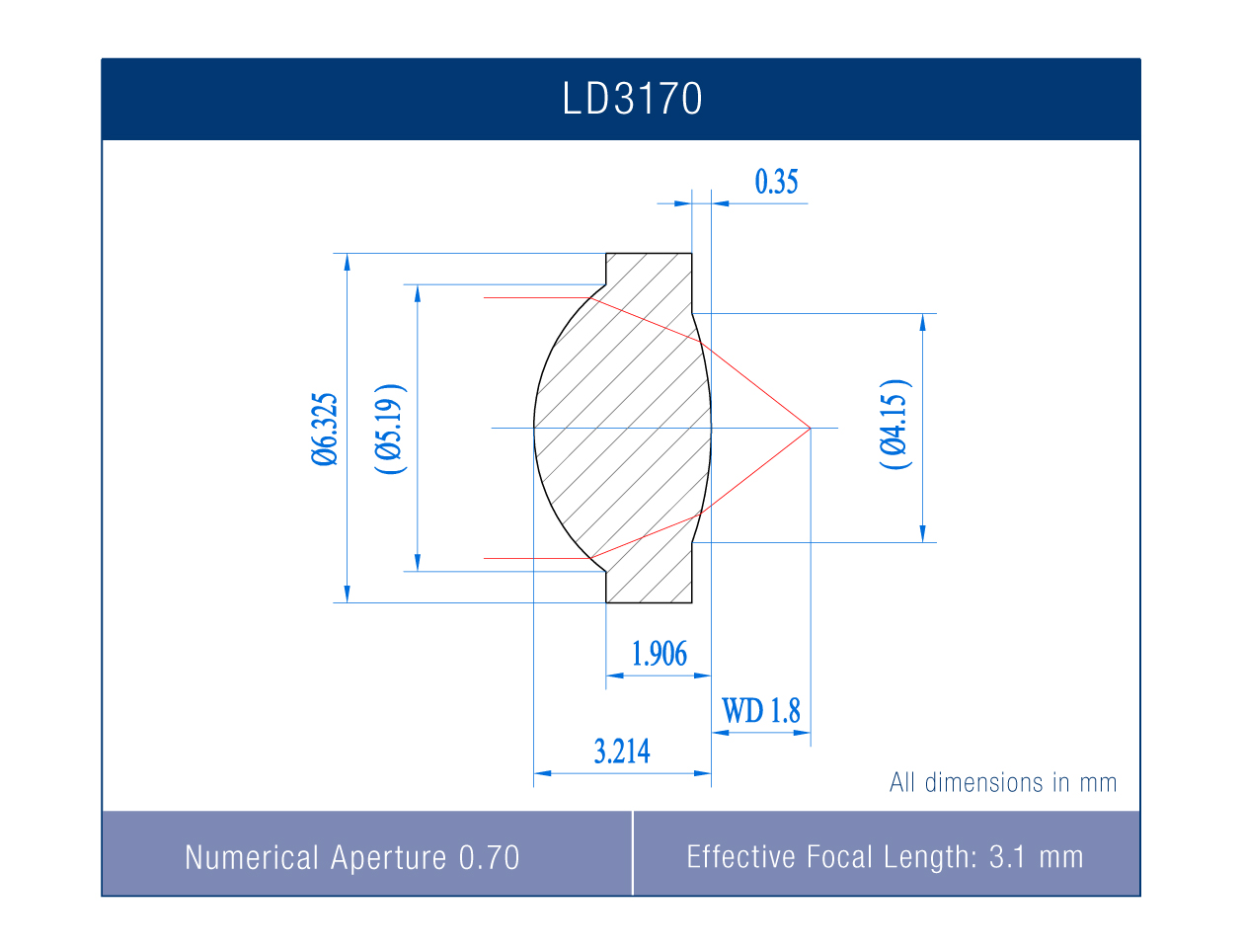

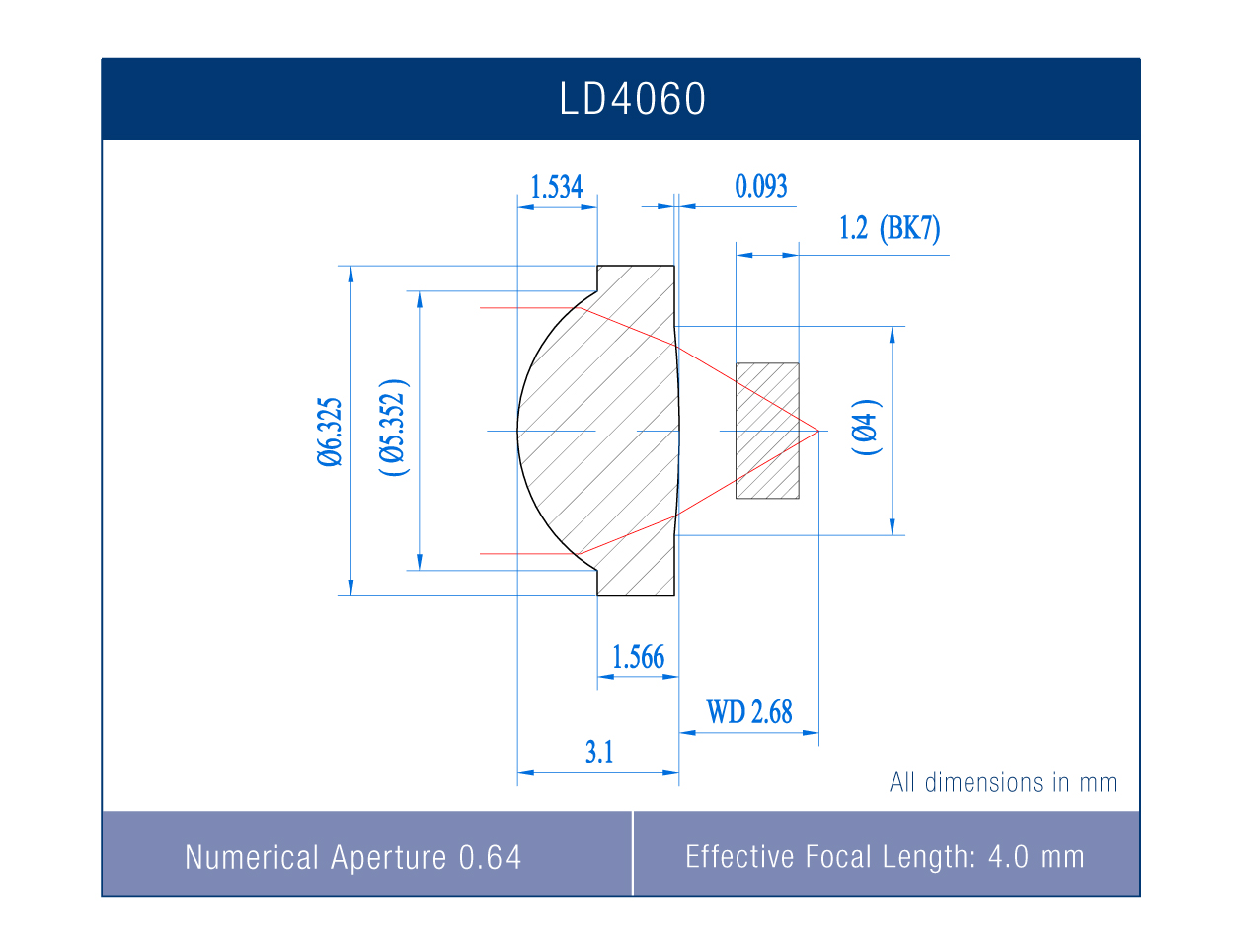

AMS Technologies offers a broad selection of molded-glass aspheric optics from stock, in sizes ranging from 2.4 mm to 11.0 mm outer diameter with focal lengths from 8 mm to 22 mm. With design wavelengths from 405 nm to 9500 nm, these molded aspheric lenses aim at applications in the visible (VIS), near-infrared (NIR) and mid-infrared (MIR) wavebands, such as small beam collimation, focusing, and fiber coupling, with our precision molded infrared aspheric lenses being ideal for coupling of quantum cascade lasers (QCL).

Standard design assemblies are available for 14 of our most popular lens types, but most aspheric lenses in our portfolio can be mounted into a custom assembly specified by the customer. Customization and design of new lenses is also available if our off-the-shelf lenses should not fit your requirements.

For large volume applications we recommend to contact your regional AMS Technologies office, so that we can tailor a solution based on your technical needs. From concept through prototyping, volume production, and global distribution, AMS Technologies has the optical knowledge and manufacturing expertise to be your optics partner every step of the way.

Our aspheric lenses are inspected and optically tested to ensure complete customer satisfaction. Visual cosmetic inspection for scratch/dig is performed on 100% of all lenses per MIL-PRF-13830B. Most lenses are guaranteed to pass 40/20 scratch/dig, but other inspection criteria, such as 60/40 or 20/10, can be provided upon request.

Product Portfolio

In addition to our ranges of standard and infrared aspheric lenses available from stock, AMS Technologies also carries a series of these precision molded aspherics mounted in stainless steel holders – equipped with threads for screwing the components into your systems, but they can also be soldered or welded to suitable structures in the required position.

Related Products

Our portfolio comprises a variety of lenses for different needs and applications that can be manufactured in diverse materials and customized based on specific requirements: spherical lenses, cylindrical lenses, achromatic lenses.

Additionally, we carry a broad range of complementary products such as fiber collimators and focusers, lens holders and lens positioniers as well as MWIR or LWIR thermal imaging assemblies .

Other available precision optics include optical windows, prisms or optical filters. All featuring high precision, smallest tolerances (dimensional and angular) and special coatings for exotic wavelengths, even into the UV spectral range.

Additionally, we carry a broad range of complementary products such as optical mounts, rotary and translation stages, optical tables, lasers and light sources as well as a broad range of optical test and measurement equipment.

Definition

While the manufacturing and use of common spherical lenses (with both lens surfaces being part of surfaces of spheres, i.e. a spherical segment or spherical cap) are less complicated and expensive, the optical performance of spherical lenses is compromised by phenomena such as spherical aberration. So instead of a simple spherical lens, a more complex shaped lens is best suited for collimating and focusing tasks – an aspherical lens with at least one surface whose shape differs from a sphere. An aspheric lens surface typically is described by a radius of curvature and several parabolic or higher order terms.

With this more sophisticated surface profile, an aspherical lens can reduce or eliminate both spherical and other aberrations, providing higher imaging quality such as a smaller focal point or a higher degree of collimation. Often, complex optical systems with multiple spherical lenses can be replaced by a single aspherical lens, resulting in less complexity, reduced dimensions, lower weight and often lower system costs.

Traditionally, aspheric lenses have been produced by complex grinding, CNC machining or diamond turning, but with advances in glass molding technology, precision molded glass aspheric lenses can now be produced at low cost while maintaining a high quality and durability, suitable even for high optical powers.

Alternative Terms: Asphere; Aspherical Lens; Non-spherical Lens