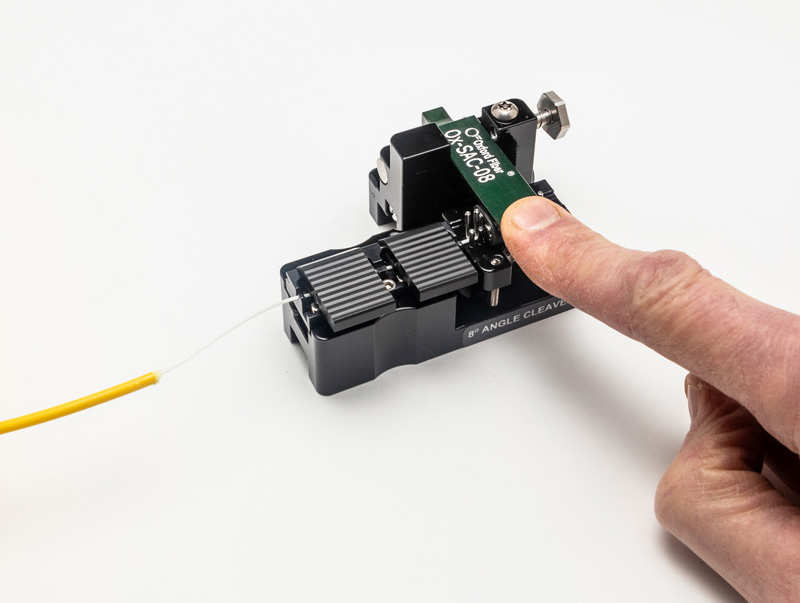

Product information "Ox-SAC-08 Diamond Angled Fiber Cleaver"

Manual Angled Cleaver; Fiber Type SM, PM; Fiber Diameter 125 µm; Buffer Diameter 250-900 µm; Cleave Angle 8° (±2°); Min. Cleave Length 8 mm

Oxford Fiber’s Ox-SAC-08 is the world’s simplest angled cleaver. The single mode (SM) or polarization maintaining (PM) fiber is clamped under rubber rings at two points and bent down onto a sharp diamond blade.

The optical fiber is cleaved so that its single mode or polarization maintaining core is at an angle of 8° from perpendicular. This way, the back-reflection from the cleaved end facet is is reduced to <-60dB, avoiding optical noise in telecom systems or eliminating reflections in fiber sensor arrays.

If you require a cleaver for any other fiber type or a custom cleaver tailored to your specifications, please get in touch with the AMS Technologies fiber cleaving experts.

Key Features:

- Staple Action for Easy Use

- Rugged Construction for Field Use

- 10 Position Diamond Bladed for Extended Life

- Blade Life: >10,000 Fibers Cleaved (Estimated)

- Benchtop and Handheld Operation

- Easy Fiber Loading Using Detachable Fiber Holder

- Compatible with Angled Mechanical Splice

- Offcut Bin, Tool Catch & Case

- Fiber Diameter: 125 μm SM or PM

- Buffer Diameter: 250 µm to 900 μm

- Cleave Angle: 8° (±2°)

- Dimensions (max): 67 mm x 40 mm x 79 mm

- Weight: 170 g

- Minimum Cleave Length: 8 mm – Set by Fiber Holder

Applications: Mechanical Field-installed Connectors; Pigtailing Fiber to Semiconductor Emitters and Detectors; Removing End-reflections in Fiber-optic Sensing Applications