Product information "ODiSI 7100 Fiber Optic Sensor Interrogators"

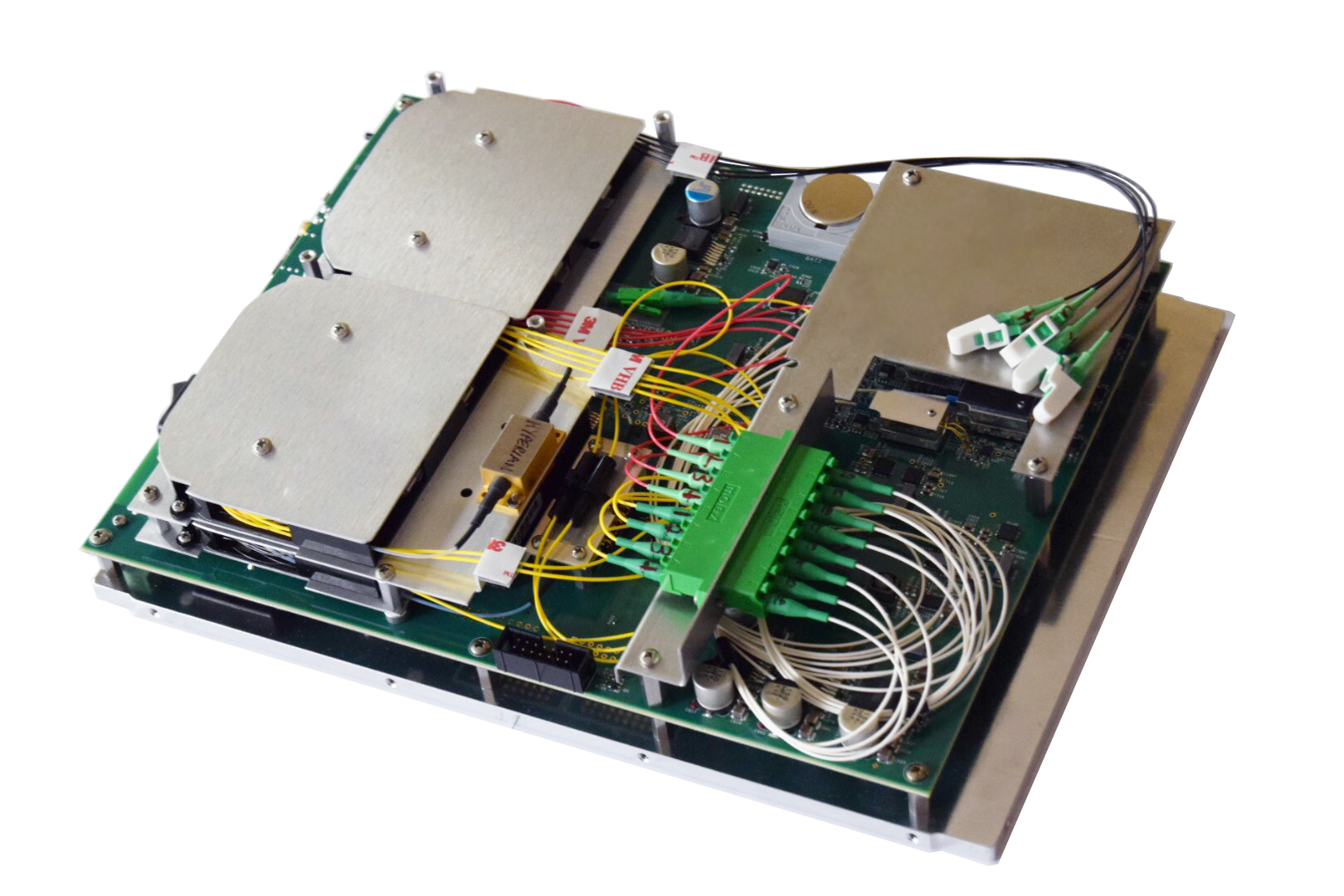

1-8 Channels; Max. Sensor Length/Channel 20m (Standard), 50 m (Extended); Measurement Points/m 384 (100 m Sensors), 1,538 (up to 20 m Sensors); Measurement Rate 2.5-250 Hz; Strain Measurement Range ±15,000 µɛ; Temperature Measurement Range -40 to 200 °C; Ethernet Data Interface

The ODiSI 7100 Series by Luna Innovations represents a breakthrough in high-definition fiber optic sensing, engineered to meet the rigorous demands of modern materials testing and structural monitoring. Designed for researchers, engineers, and industrial users, this advanced system delivers unparalleled spatial resolution and real-time data acquisition for strain and temperature measurements. With the ability to capture thousands of data points per meter, the ODiSI 7100 enables comprehensive insight into the behavior of materials and systems under dynamic conditions.

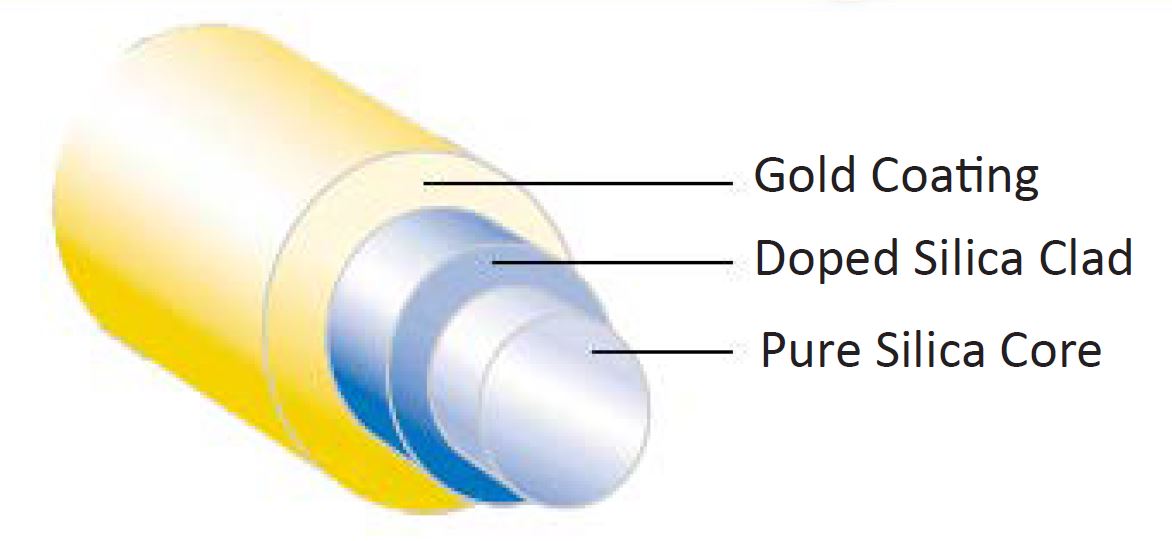

Unlike traditional point sensors, the ODiSI 7100 leverages distributed sensing technology to provide continuous measurement along the entire length of a fiber optic sensor. This capability is critical for applications requiring high fidelity model validation, process optimization, and structural health monitoring. The system’s passive, dielectric sensors are corrosion-resistant and immune to electromagnetic interference, making them ideal for deployment in challenging environments, including embedded installations and sharply curved surfaces.

Key Features

The ODiSI 7100 Series sets a new standard in distributed fiber optic sensing with the following key features:

- High-definition distributed sensing: Achieve sub-millimeter gage pitch with up to 1,538 measurements per meter, enabling detailed strain and temperature mapping.

- Multichannel architecture: Supports up to 8 channels, each capable of handling up to 100 meters of sensing fiber, allowing for scalable and flexible deployment.

- Real-time data acquisition: Provides immediate feedback from demanding environments, facilitating rapid decision-making and process control.

- Robust sensor design: Flexible, lightweight, and easy to install, the sensors require no electrical power and offer long-term stability without recalibration.

- Extended reach: Standoff cable lengths of up to 200 meters per channel enable remote sensing in hard-to-access locations.

Applications

The versatility and precision of the ODiSI 7100 Series make it suitable for a wide range of technical applications:

- Advanced materials characterization: Capture strain profiles in composites, metals, and hybrid materials to support R&D and quality assurance.

- Process optimization: Monitor in-situ temperature distributions to enhance efficiency in manufacturing and energy systems.

- Finite element model validation: Measure two- and three-dimensional strain fields to verify simulation accuracy.

- Structural integrity assessment: Detect micro-cracks and defects in aerospace, automotive, and civil infrastructure components.

- Smart part integration: Embed sensors within materials to create intelligent components capable of self-monitoring.

What's Next?

The ODiSI 7100 Series is more than a sensor system, it’s a platform for innovation. Whether you're developing next-generation aerospace structures, optimizing battery performance, or validating complex simulations, the ODiSI 7100 delivers the data density and reliability needed to push boundaries. Its seamless integration with Luna’s visualization and analysis software further enhances usability and insight.

To explore how the ODiSI 7100 Series can elevate your research or industrial application, contact our sales team today for a personalized consultation or quote.