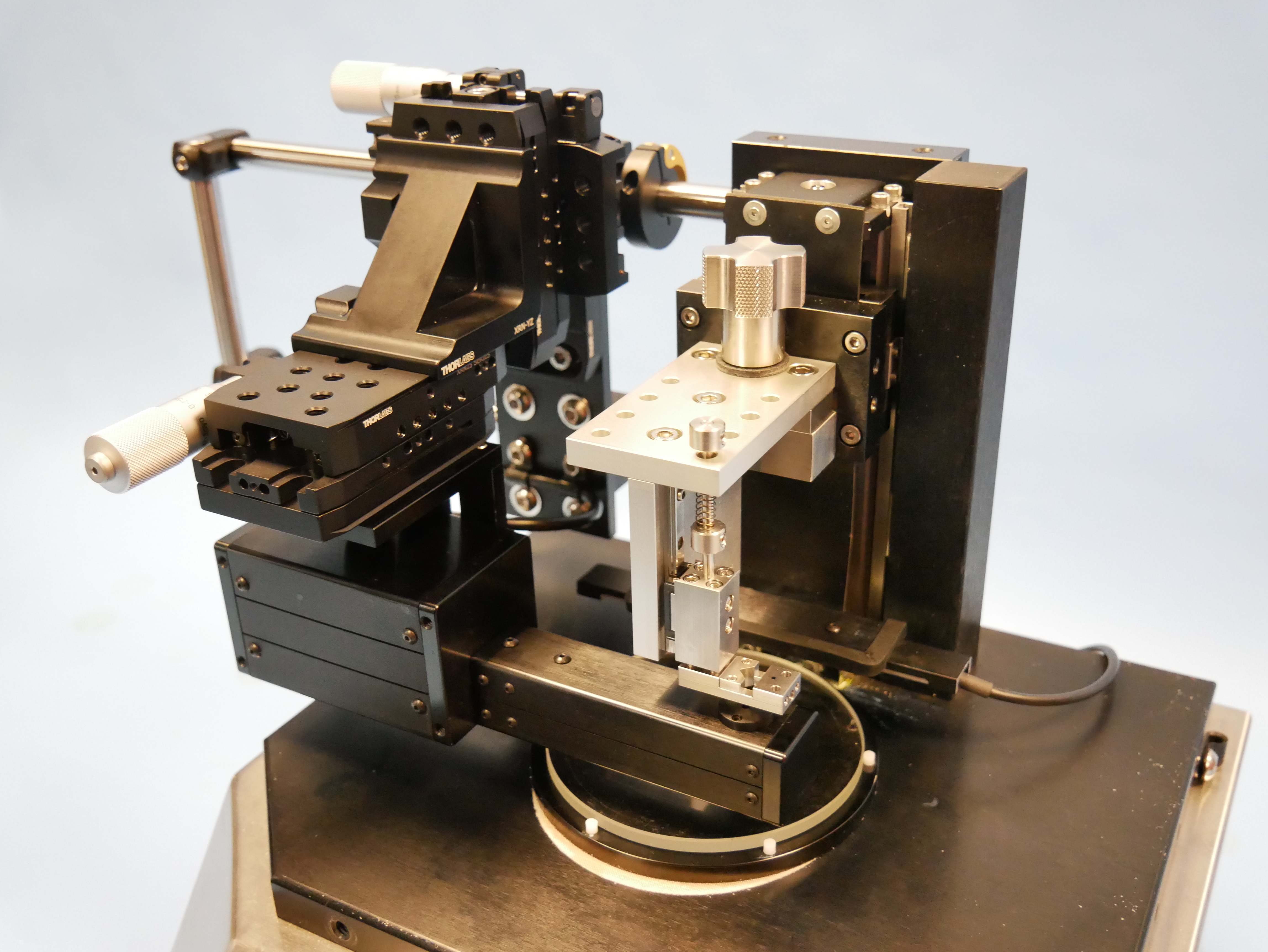

Product information "NOVA Surface Inspection Module"

Surface Inspection Microscope Module for NOVA™ Polishing System

As an option for its NOVA™ automated polishing system, KrellTech offers video inspection systems to monitor the polishing process and inspect the polished surface directly in NOVA™.

KrellTech’s NOVA™ surface videoscope allows the in-line inspection of polished surfaces while the component is still loaded in the polisher. This minimizes material handling and streamlines photonic production compared to the traditional process of transferring components to off-line inspection stations. Polishing and specification compliance can be determined in a single workcell.

Teamed with measurement software, this system verifies the endface geometry of a broad range of photonics components, from optical fibers, waveguides and arrays all the way to inspecting the results of PIC (Photonic Integrated Circuits) post production processing.

Applications: Inspecting and verifying the polishing process and the endface geometry of optical fibers, waveguides, arrays and PICs