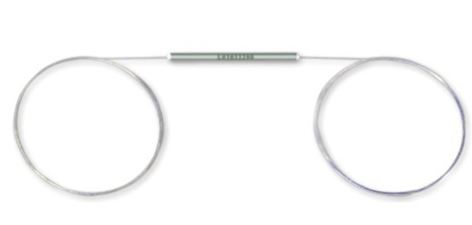

Product information "FUSED PM Couplers & Combiners"

Polarisation Maintaining Couplers & Combiners; 780 to 2005 nm; Splitting Ratio 50/50, 90/10, 95/5; Return Loss <50 dB; Directivity <55 dB

Fusing and tapering the fibers together is a simple, rugged, compact method of splitting or combining optical signals. Typical excess losses are as low as 0.2 dB, while split ratio tolerances range from ±5% to ±0.5% at design wavelengths depending upon the splitting ratio.

OZ Optics’ PM Fused Fiber Couplers are bidirectional and offer low backreflection and insertion losses. They exhibit a broad operating wavelength range of up to ±20 nm for 1550 nm region devices. Fused PM splitters are also available on smaller core fibers for 1064 nm, 980 nm and other wavelengths. (Nonstandard center wavelengths may require minimum order quantities or set up charges. Please contact AMS Technologies for assistance).

A wide variety of options are available for fused PM splitters. Standard configurations are 1x2, 2x2, 1x3 (monolithic) and 1x4 (compact cascaded). A monolithic structure means that all fibers are fused together, while a cascaded device combines several 2x2 splitters to create a greater split count. OZ Optics can design and construct larger split counts or different split ratios upon request.

OZ Optics has the capability to connectorize the fibers of fused splitters with all standard connectors such as FC, SC, ST, LC etc. and finishes (Super PC, Ultra PC, Angled PC [APC] etc.). As a component integrator, OZ Optics can construct additional components such as tunable filters, variable attenuators, or collimators directly onto the coupler fibers.

In general OZ Optics uses polarization maintaining fibers based on the PANDA fiber structure when building polarization maintaining components. However OZ Optics can construct devices using other PM fiber structures and does carry some alternative fiber types in stock, so please contact AMS Technologies for availability. If necessary, OZ Optics is willing to use customer supplied fibers to build devices.

Key Features:

Wide Variety of Wavelengths 780 nm to 2005 nm

Low Loss - Broad Bandwidth

Good Uniformity

Small Package

High Directivity

Wide Variety of Wavelengths 780 nm–2005 nm

Applications: Optical Amplifiers; Fiber Lasers; Power Monitoring; Fiber Gyroscopes; Coherent Communications