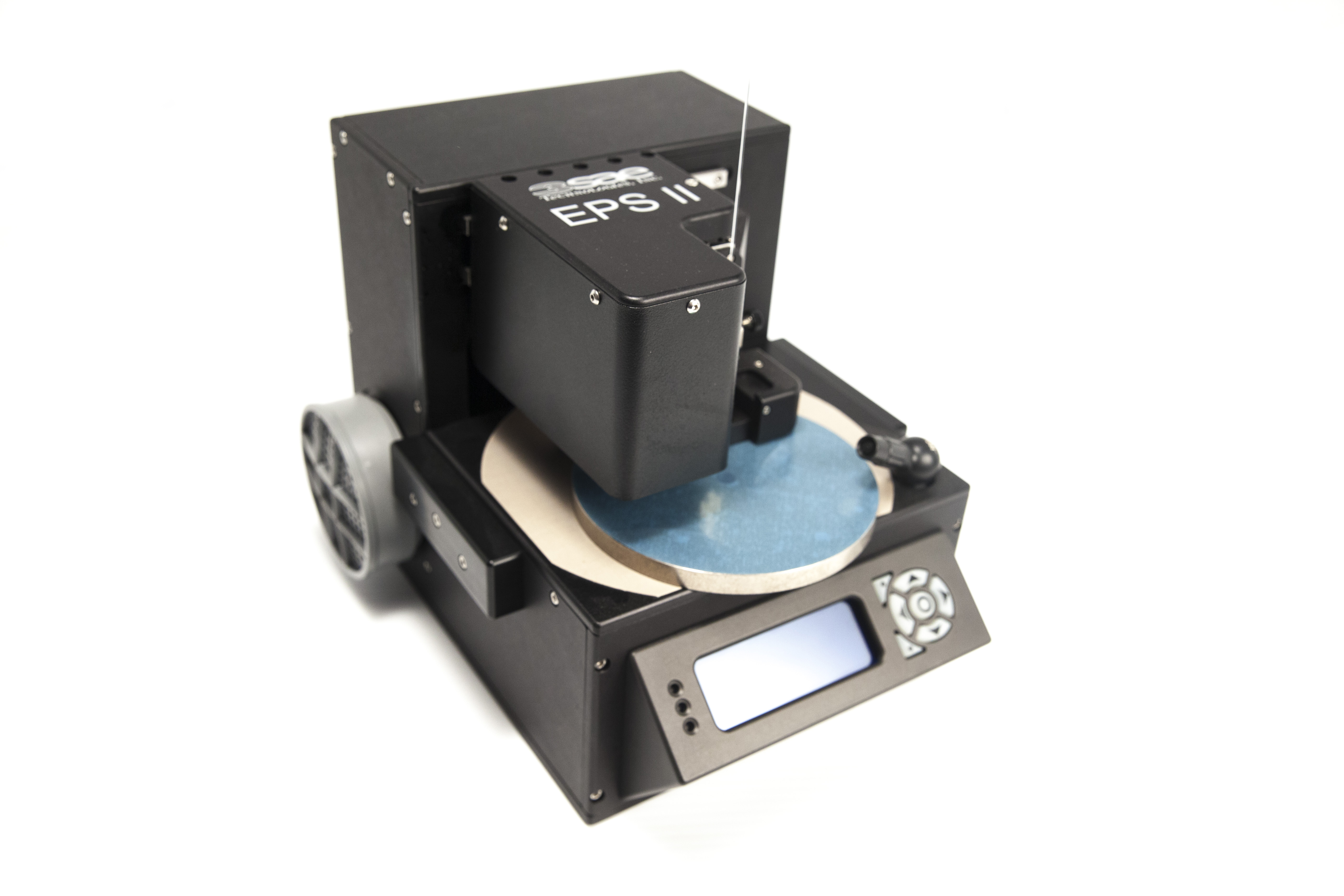

Product information "EPS II End Face Preparation Station"

Fiber Type Large Diameter (LD); Fiber Cladding 400-2,000 µm; Non-angle or Angle Polishing <0.30-15° Typ.; Cycle Time 1-3 min; Scrap Fiber Waste <2 mm Typ.

Large diameter (LD) optical fibers are increasingly important in the development of new optical technologies. Cleaving these fibers presents many challenges, more so as the fiber diameter increases. Low angle offsets and smooth, flat end faces are required. Many fibers are non-round or have internal structures that interfere with conventional cleaving. With some fibers priced in hundreds of euros per meter, the length of cutoff scrap must be minimized.

3SAE Technologies’ EPS II End Face Preparation Station meets these challenges with a novel, polishing-based design that now features both flat and angle polishing. The results are consistent, even for shaped fibers. The end faces are flat and highly polished.

EPS II is not an adapted connector polisher – it is a purpose-built large diameter (LD) optical fiber preparation unit optimized for splicing and other large diameter fiber termination applications.

Choose from a selection of standard programs, or create and store a custom program for a specific fiber. Selectable programs ensure repeatable performance and the bright, clear LCD screen guides the user with the correct action for each step. No special skill or “touch” is required –the EPS II’s precision fixturing holds the fibers precisely, and the automated system lowers the fibers smoothly onto the adjustable-speed polishing plate.

A filtered-air final cleaning/drying system is used to dry the fiber after cleaning in the included 3SAE Technologies Ultrasonic Cleaner, a purpose-built ultrasonic fiber cleaner that was designed specifically for fiber applications. Many years of splicing experience went into the functional, ergonomic design that ensures consistent cleaning results.

When the preparation process is complete, the fiber end faces are flat, low-angle and ready for splicing. Less than 2 mm of scrap length means less wasted expensive fiber and allows more accurate placement of splices and components.

Key Features:

- Angled Polishing Capabilities

- High First-pass Yield

- Lowest Available Cleave Angles: <0.30° Typical

- Scrap Fiber Waste: <2 mm Typical

- Fiber Cladding: 400 to 2,000 µm

- Angle Cleaving: Up to 15° of Rotation (From Vertical)

- Cycle Time: 1 to 3 min Per Fiber Typical

- Easy Handling, No Additional Fiber Handling System Required

- Operator Independent

- No PC Required

- Power Supply: 24 VDC External

- Dimensions: 299.7 x 292 x 223.5 mm

- Compressed Air: Max 95 psi, 0.6 SCMF

Applications: Splicing of Large Diameter (LD) Fibers up to 2,000 µm Fiber Cladding; Other Large Diameter (LD) Fiber Termination Applications